Company

Top Message

-

『Run for the Next』

For more than 80 years since our founding in 1935, we have been committed to “monozukuri” (manufacturing).

We have grown into a company that is able to respond quickly to customer requests with our advanced technology and ability to make proposals. We do not have a dedicated production line, but use general-purpose equipment, and our flexible response is possible by devising manufacturing methods and dies.Under the management philosophy of『Honest and straightforward manufacturing that never betrays the world』and the slogan 『Run for the Next』we will continue to provide “products” that can solve our customers’ “problems” and “needs” promptly and accurately, and will continue to strive to be a “pipeline” that connects various things in various situations, just like our products.

Jun Kumada , President

Profile

Management Philosophy

“Honest and straightforward manufacturing that does not betray the world.”

Quality Policy

“100% assurance of the quality demanded by our customers.”

| Company name | HOHSEI INDUSTRIAL CO., LTD. |

|---|---|

| representative | president & representative director Jun Kumada |

| Location of Head Office/Main Plant | 6-24-1, Nissai Hanamizuki, Sakado City, Saitama Prefecture, 350-0269 TEL 049-288-7171 FAX 049-288-7181 |

| Location of Shin-Shirakawa Plant | 10 Kajiyabatake, Habuto, Nishigo-Mura, Nishishirakawa-gun, Fukushima Prefecture, 961-8001 TEL 0248-25-1673 FAX 0248-25-2562 |

| Capital | 80 million yen |

| Founded in | 1935. |

| Employees | 118(As of October 2022) |

| Main Clients | Honda Motor Co., Ltd. / Honda R&D Co., Ltd. / Honda Foundry Co., Ltd. / metts corporation. / MIKUNI PARTEC CO., LTD / OHASHI TECHNICA, Inc / YAMADA MANUFACTURING CO., LTD. / Honda Trading Corporation / Keihin Seimitsu Kogyo Co., Ltd. / Mitsubishi Electric Corporation / Hitachi Astemo, Ltd. / Toyota Tsusho Corporation. / MEIDENSHA CORPORATION (in no particular order) |

| Major Banks | MUFG Bank, Ltd. Shimura Branch / The Musashino Bank,Ltd. Sakado Branch / Saitama Resona Bank,Limited Sakado Branch / Sumitomo Mitsui Banking Corporation Sakado Branch / THE TOHO BANK, LTD. Shirakawa-nishi Branch |

| Authentication | ISO9001/14001 |

Location Information

-

Head Office/Main Plant

【Address】

6-24-1, Nissai Hanamizuki, Sakado City, Saitama Prefecture, 350-0269

TEL:049-288-7171【Access】

Institution: Get off at Kita-Sakado Station (West Exit) on the Tobu Tojo Line.

- Approx. 15 minutes by local bus

⇒Nissaidanchi loop line/Nissaidanchi subway 3 minutes walk - Approx. 10 minutes by cab

Automobile: 5 minutes after exiting at the Sakado Nishi Smart Interchange on the Kanetsu Expressway - Approx. 15 minutes by local bus

-

Shin-Shirakawa Plant

【Address】

10 Kajiyabatake, Habuto, Nishigo-Mura, Nishishirakawa-gun, Fukushima Prefecture, 961-8001

TEL:0248-25-1673【Access】

Institution: 15 minutes by cab from Shin-Shirakawa Station (Takahara Exit) on the Tohoku Shinkansen Line Automobile: 15 minutes after exiting at the Shirakawa Interchange on the Tohoku Expressway

Facilities

Main production facilities

| Presses (mechanical, hydraulic, servo) | 42 units |

|---|---|

| CNC Bender (Vertical/horizontal type) | 14 units |

| CNC Robot | 11 units |

| End processing machine | 11 units |

| Working | 4 units |

| Rolling machine | 8 units |

| NC Lathe/Screw device type NC Lathe | 59 units |

| Tapping Machines | 22 units |

| Bench race | 12 units |

| Milling machine | 3 units |

| Blasting Machine | 4 units |

| Machining center | 1 units |

| Water-based through-type washer | 1 units |

| Hydrocarbon-based cleaners | 3 units |

| Other | 37 units |

Main measuring instruments

| 3D Coordinate Measuring Machine | 1 unit |

|---|---|

| Roundness measuring machine | 2 unit |

| Shape Measuring Machine | 2 unit |

| Surface Roughness Measuring Machine | 1 unit |

| Hardness tester | 3 unit |

| Projector | 2 unit |

| Metallurgical microscope | 1 unit |

| Roller sorting machine | 3 unit |

Vendor machines

-

-

【Processing content】

- Pipe bending

Capable of 2-D and 3-D bending, including 90° and 180° bending, and other optimum equipment such as vertical and horizontal bending can be selected according to specifications.

Supports ultra-small radius bending, which contributes to space saving.

【Effective work size】

- Outer diameterΦ32

- Maximum length 1,300mm

※The processing range varies depending on various conditions such as material, shape, and plate thickness, so please consult with us on a case-by-case basis.

- Pipe bending

Press machine(45t, 60t, 80t)

-

-

【Processing content】

- From plastic forming such as tube expansion, bending, and drawing to drilling, we can handle small-lot production to labor-saving large-lot production using robots.

In addition, motion control by using a servo press enables higher precision machining.

【Actual work size】

- φ3~φ60

※The processing range varies depending on various conditions such as material, shape, and plate thickness, so please consult with us on a case-by-case basis.

- From plastic forming such as tube expansion, bending, and drawing to drilling, we can handle small-lot production to labor-saving large-lot production using robots.

Terminal processing machine/working (horizontal press machine)

-

-

【Processing content】

- Plastic forming such as tube expansion, drawing, etc.

The horizontal type can handle long workpieces (max. 1,000 mm or so).

Also, since it can process from 1 punch to 6 punches, it can support multiple processing with a single chuck.

【Processable work size】

- ~Φ40

※The processing range varies depending on various conditions such as material, shape, and plate thickness, so please consult with us on a case-by-case basis.

- Plastic forming such as tube expansion, drawing, etc.

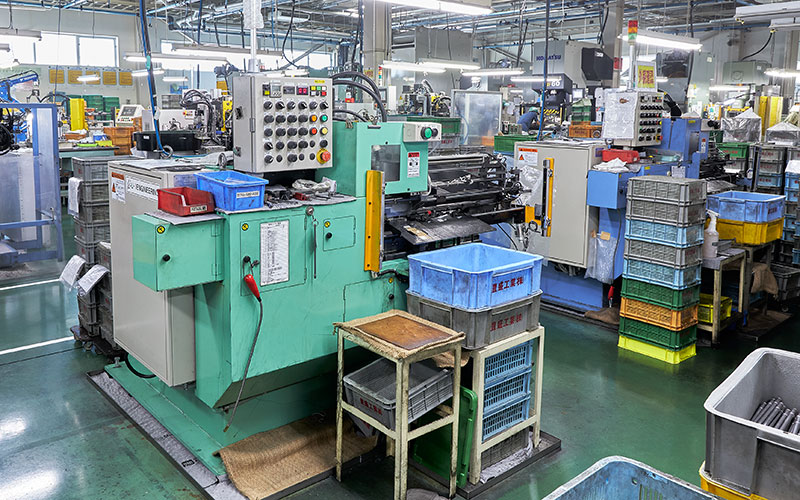

NC Lathe

-

-

【Processing content】

- Supports various cutting processes (drilling, threading, adjustable cutting, etc.)

Stable supply is available from Bar materials to finished products, small lot processing, and large lot processing through automation.

- Supports various cutting processes (drilling, threading, adjustable cutting, etc.)

Contact

For more information about our products, please contact us from the following link.