Products

Technologies

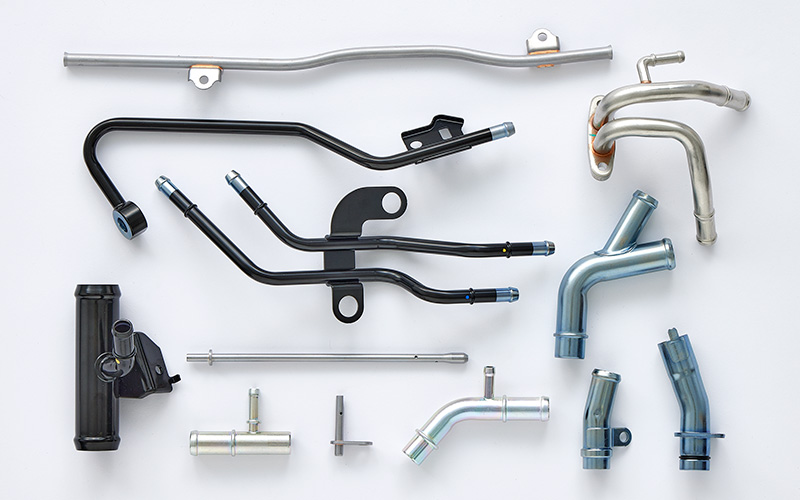

Pipe

- Bender bending

-

Flexible bending with minimal deformation is possible using dies for minute radius bending and multi-turn bending.

Minimum bending center R: 0.75D(D=Pipe Outer Diameter)

※0.6D is also possible under certain conditions.Bending sectional area reduction rate: 13% or less

- Press bending

-

A bending method using a press, characterized by stable processing using dies and fast tact time. We can also process according to your requirements, such as single to multiple bending.

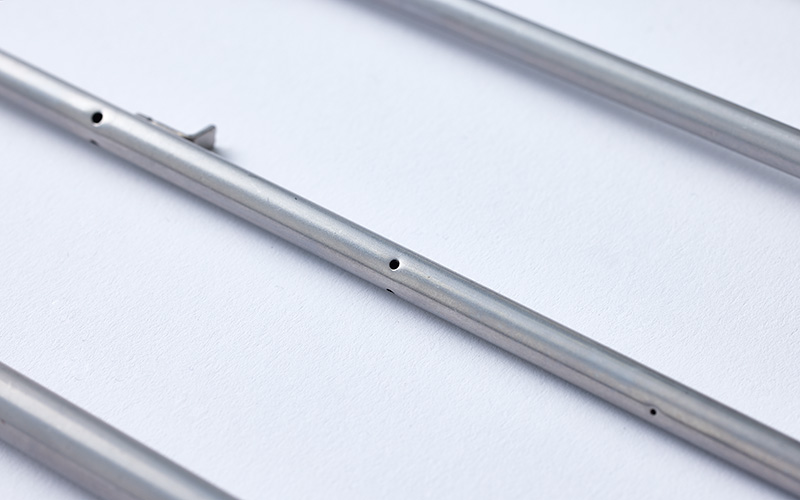

- Drilling process

-

By using presses and dies instead of cutting machines, fine hole drilling is possible. Several holes can be drilled at the same time, and the level of drilling is such that no burr treatment is required.

- Brazing process

-

Processing of joining brackets, branch pipes, etc. to pipes. Leak tests and jig inspections after brazing are also conducted.

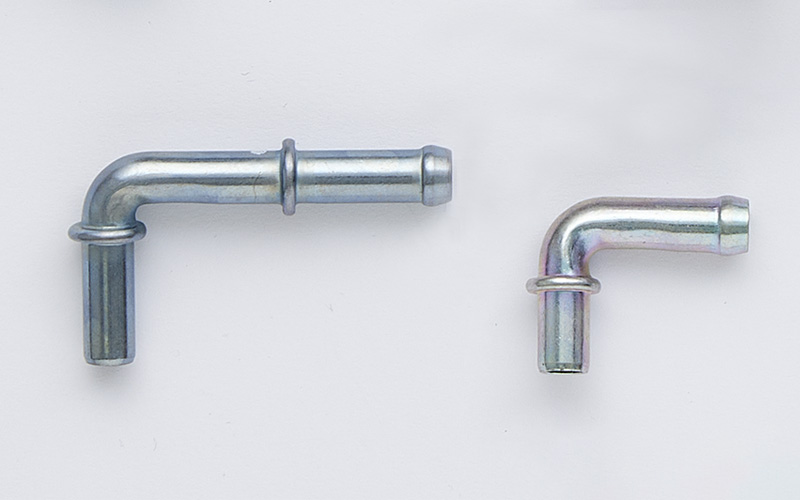

- Stepped process

-

Hose stopper formation by step machining and precision finishing of press-fit parts are possible.

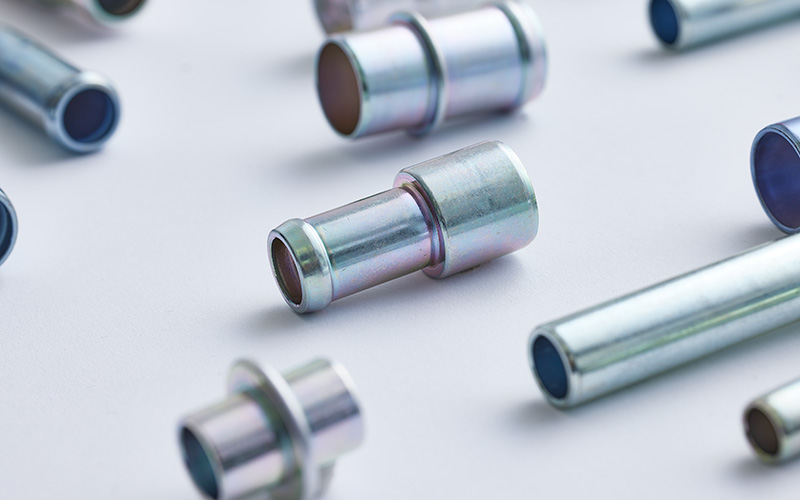

- Rolling process

-

Material can be used without waste by rolling with dies, such as screws and O-ring grooves.

Deformed process

Nut shape, oval, crushed, and other shapes of your choice are available.

Contact

For more information about our products, please contact us from the following link.